Zhengzhou good companyZCSeries turn bed is for thermal spraying shaft, roller, ball valve parts and design and manufacture of special equipment, shaped like a lathe, transverse loading role mainly in the spraying process parts card and spin, so called "bed".This series of products based on the different customization of the clamping workpiece load, turn the bed mechanical structure design is reasonable, not only effectively stop the dust on the influence of transmission parts, due to the high quality materials and components assembly, more to ensure durability.

The equipment control adopts touch screen man-machine interface, can be defined speed or simple plait after spraying different artifacts.And, of course, can also be walking with a gun manipulator linkage, Shared a touch screen, turn to complete the bed set speed and walking speed and the manipulator motion of manipulator.Turn the bed can form with manipulator, spraying core equipment safety chain, ensure the safety of the workpiece and operators.

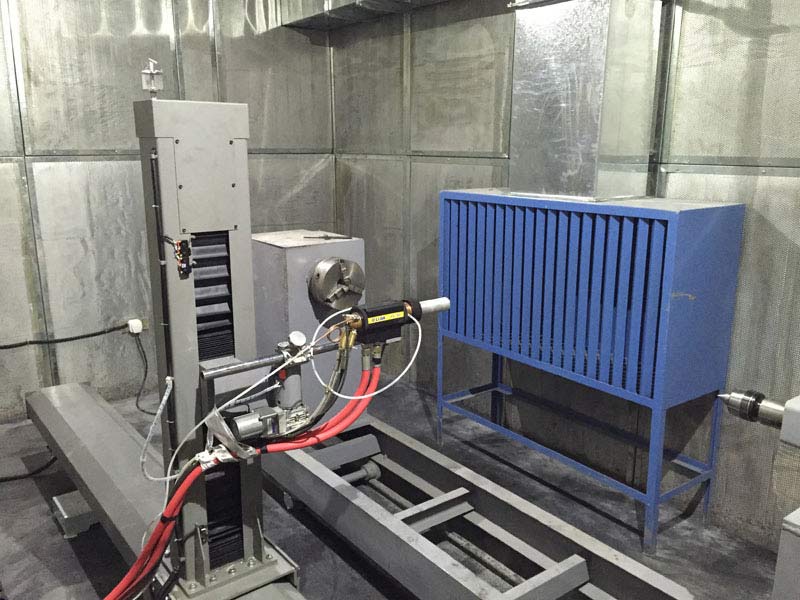

Horizontal rotary bed designed for the realization of long axial workpiece spraying processing design.Horizontal work to pack artifact card in the car, driven by frequency conversion motor artifacts by setting the average rotation, rotation speed can be adjusted, with automatic spray gun, spraying workpiece surface of all processing.

Lathe bed power for electric drive, bed load10TInclude tooling, turn to the composition and structure of bed: it is composed of power head, bracket, lathe bed, base composition.

Second, the features and advantages:

1, professional design for thermal spraying, dustproof heat resistant, durable.

2, the use of advanced servo motor, speed precision equipment, ensure the coating thickness of consistency.

3, adopt touch screen man-machine interface, can be set rotation speed.If the walk and manipulator linkage with walking robots Shared a man-machine interface, which can realize more complex spraying process

4, can provide customers with different load level, the standard is0.5Tons,1Tons,5Tons of three

5, turn on either side of the bed is chuck, top form, turn the bed can adjust itself according to workpiece length of the length of the card, the top end is manual rocker arm movement, transmission parts for effective dust protection

6, as a result of spraying the workpiece diameter is different, the speed of rotation also needs to have different Settings, turn turn rotation speed can be up to thousands of beds/Minutes, so the applicable scope of workpiece diameter is very large

7、ZCSeries turn bed changed the traditional dependence on slow time for flexible way stop stop, stop the precise control on spindle braking torque (not dead), under the condition of the machine does not produce vibration, the spindle rotating inertia braking torque by eliminating until the stop.Compared to rely on the deceleration time to stop, to avoid the deceleration time Settings are too short,Mechanical shock, slow setting time is too long cause lower efficiency, with speed problem such as slow response, more intelligent, efficient, prolong mechanical life.

8、ZCSeries turn bed can form with manipulator, spraying core equipment safety chain, ensure the safety of the workpiece and operators.

9, the equipment using company's proprietary dustproof design.

10And all theLQLSeries turn bed are equipped with before they go out0.5 5Tons of test sample roll for sufficient reliability test, to ensure operation completely standard rear can deliver goods.

Technical parameters:

|

The basic performance parameters of the bed |

|

|

Turn the bed type |

ZC500 |

|

The largest capacity |

500kg |

|

The spindle rotation speed |

0-400rpm (Can be higher) |

|

Rotation speed volatility |

0.002% - 0.5%. |

|

The spindle drive |

Ac brushless servo motor |

|

Can install card workpiece length |

0mm-1500mm(optional) |

|

The tailstock mobile device drivers |

Frequency control of motor speed |

|

Overall dimensions |

3200mmX900mmX1000mm(Three high) |