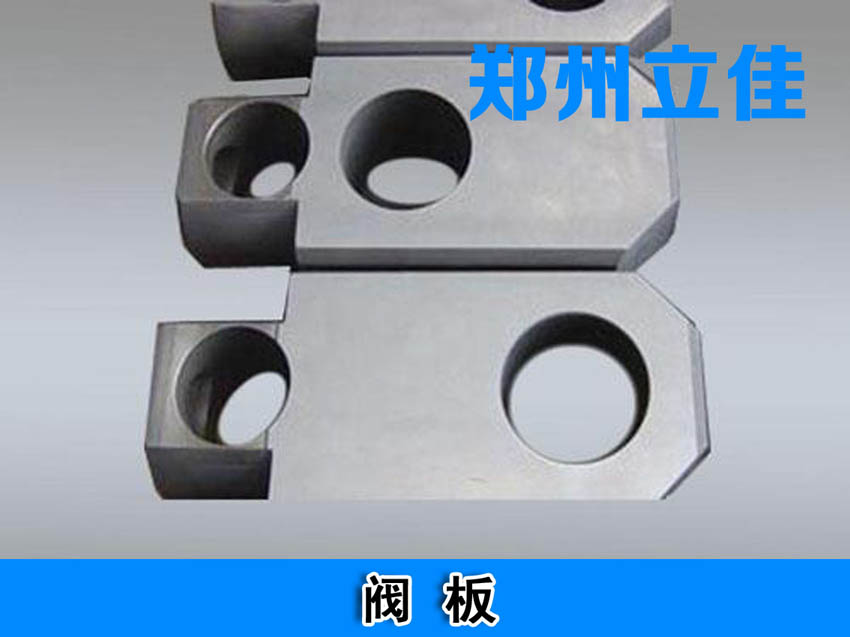

This article adopts the supersonic flame spraying production, the product coating hardness up to HV1200-1600 (HRC75), strong bonding force, porosity < 1%, mainly to avoid the spray welding and welding quality is not stable, caused by the pore products completely by nondestructive flaw detection, high wear resistance and corrosion resistance of products are mainly used for industrial and mining, such as oil and gas fields and the deep sea., the whole ram and valves, due to the different material and the pressure and the working temperature can have bigger difference, welcome to inquire!

Zhengzhou; thermal spraying machinery co., LTD. As the leading enterprise in henan thermal spraying industry, is a professional engaged in research and development of thermal spraying processing and equipment manufacturing of high and new technology innovation enterprise, the company to undertake a variety of spraying processing and mechanical processing business, the thermal spraying technique power is strong, after the hot spraying coating design and coating processing, supersonic flame spraying equipment has experienced, innovative ideas, to solve some key problems in the field of thermal spraying related applications.The company has more multi-purpose spraying room, equipped with a robotic arm, complete all kinds of tooling, can ensure good coating quality.Company also is equipped with lathes, milling machine, drilling machine, and the universal grinding machine can undertake various mechanical processing business, and coating surface grinding business.

The company's aim is: to create the world first-class technology and equipment, to provide customers with high quality and high quality service, honesty, innovation and progress.Actively accept user valuable advice in equipment use and coating processing.Wholeheartedly for the users from all walks of life both at home and abroad to provide quality service!

The above quotation will be subject to actual consultation!