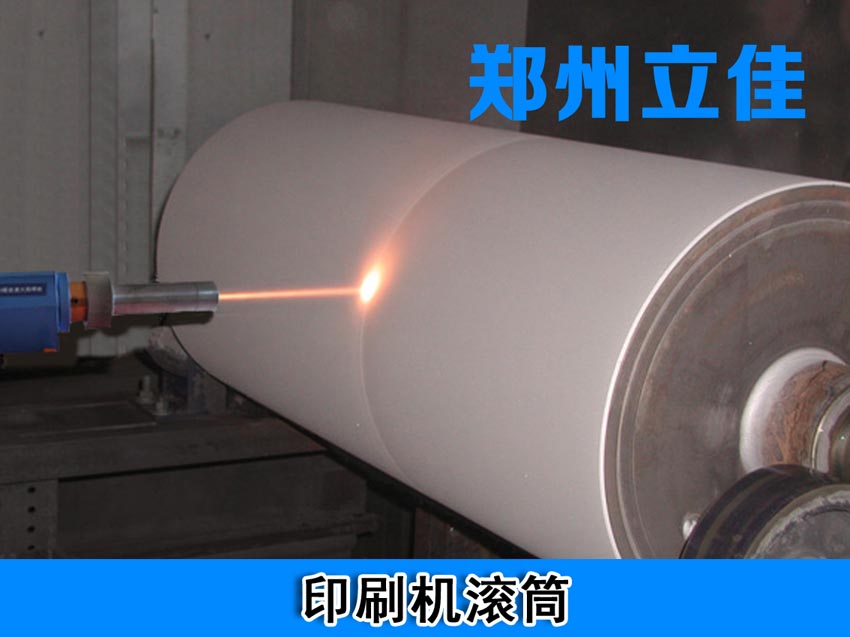

Wear-resisting coating printing press roller with supersonic flame spraying, tungsten carbide coating is better than traditional chilled cast iron roll shows excellent wear resistance.Microhardness of tungsten carbide coatingHV1300, which is equivalent toHRc75And the hard chromium plating and the hardness also can only achieve chilled cast ironHRc65, according to foreign relevant materials, the wear resistance of sprayed tungsten carbide coating for chilled cast iron10Times.Tungsten carbide coating8GPaRolling contact fatigue strength, can withstand the calender roller grinding pressure;Because of the compact coating nonporous, corrosion resistance is superior to plating roller surface;Compact coating can grind to a mirror finish, in the ordinary steel roller coating the surface of the tungsten carbide coating, can avoid the chilled cast iron casting defects.

Zhengzhou; thermal spraying machinery co., LTD. As the leading enterprise in henan thermal spraying industry,Is a professional engaged in thermal spraying processing and equipment manufacturing research and development of high and new technology enterprise innovation, Supersonic flame spraying equipment, and undertake all kinds of spray processing and mechanical processing business, the thermal spraying technique power is strong, after the hot spraying coating design and coating processing, supersonic flame spraying equipment has experienced, innovative ideas, to solve some key problems in the field of thermal spraying related applications.The company has more multi-purpose spraying room, equipped with a robotic arm, complete all kinds of tooling, can ensure good coating quality.Company also is equipped with lathes, milling machine, drilling machine, and the universal grinding machine can undertake various mechanical processing business, and coating surface grinding business.

The company's aim is: to create the world first-class technology and equipment, to provide customers with high quality and high quality service, honesty, innovation and progress.Actively accept user valuable advice in equipment use and coating processing.Wholeheartedly for the users from all walks of life both at home and abroad to provide quality services!