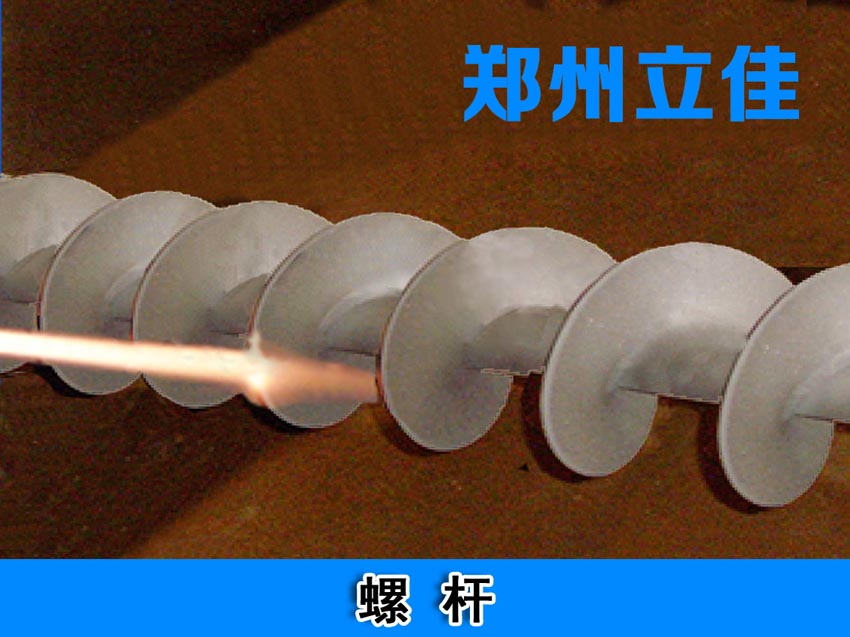

Process: the supersonic spraying screw

Spraying materials: tungsten carbide Chromium carbide Nickel base alloy Cobalt base alloy Iron base alloy Due to the division of nickel alloy Monel alloy

Performance: high temperature resistant Resistance to high pressure Corrosion resistant Resistant to wear and tear

Machining precision (roundness) :0.01 to 0.04mm

Coating thickness: according to customer requirements for processing

service:To provide a full range of technical support and subsequent processing.

Zhengzhou; thermal spraying machinery co., LTD. As the leading enterprise in henan thermal spraying industry,Is a professional engaged in thermal spraying processing and equipment manufacturing research and development of high and new technology enterprise innovation, Supersonic flame spraying equipment, and undertake all kinds of spray processing and mechanical processing business, the thermal spraying technique power is strong, after the hot spraying coating design and coating processing, supersonic flame spraying equipment has experienced, innovative ideas, to solve some key problems in the field of thermal spraying related applications.The company has more multi-purpose spraying room, equipped with a robotic arm, complete all kinds of tooling, can ensure good coating quality.Company also is equipped with lathes, milling machine, drilling machine, and the universal grinding machine can undertake various mechanical processing business, and coating surface grinding business.

The company's aim is: to create the world first-class technology and equipment, to provide customers with high quality and high quality service, honesty, innovation and progress.Actively accept user valuable advice in equipment use and coating processing.Wholeheartedly for the users from all walks of life both at home and abroad to provide quality services!