A, Supersonic flame spraying tungsten carbide performance metrics

Hardness up to:HRC70~80

Bonding strength:≥90MPa

High temperature resistant to:1200℃The above

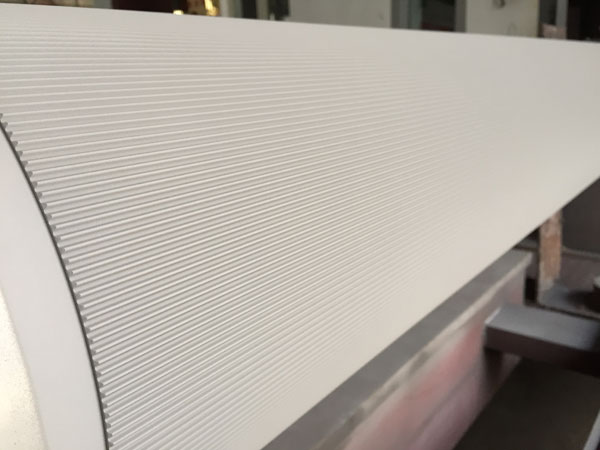

The surface roughness:Ra0.2

Strong corrosion resistance, not easy deformation

Coating thickness:0.04mm~0.1mm

straight line C:0.015mm-1000mm

Second, The supersonic flame spraying tungsten carbide in the application of the corrugated roller

1And the thermal spraying tungsten carbide corrugated roll applications

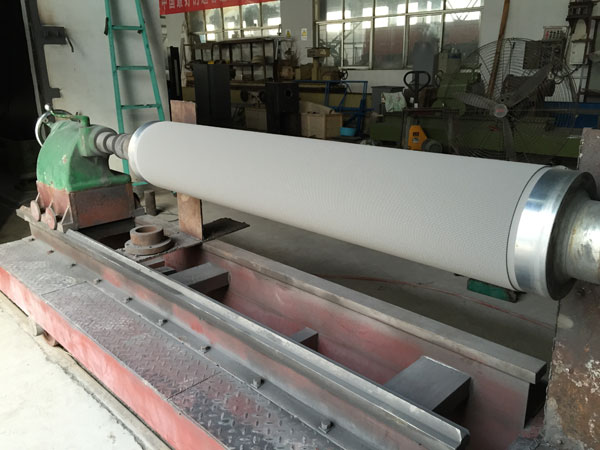

A, new corrugated roller coating tungsten carbide

BChange, old corrugated roller and tungsten carbide

CAnd tungsten carbide corrugated roll repair New tungsten carbide corrugated roll coating thickness0.05~0.1mm, when the long-term use of coating to reduce, not production, we again for you to remove residual tungsten carbide repair, corrugated roller diameter is almost not changed.

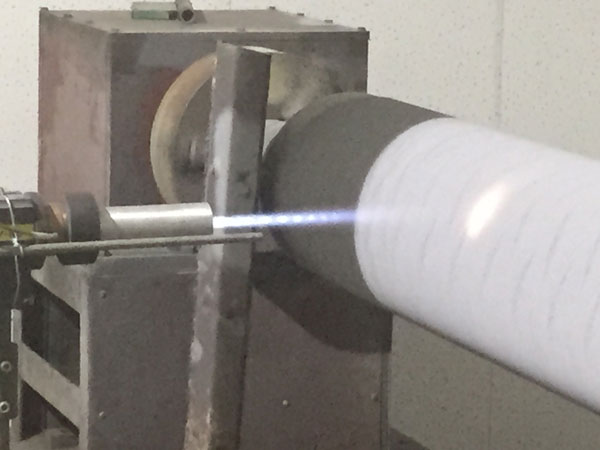

2And tungsten carbide corrugated roll process

Tungsten carbide corrugated roll process, unlike traditional corrugated roller, before the first matrix hardness, heat treatment before spraying the shape accuracy is higher, must be finished on the fully automatic CNC grinding, followed by spraying technology is the key, to ensure the hardness of tungsten carbide binding force and the quality of the polishing processing, after is one of the most difficult machining after spraying polishing technology, because of the corrugated roller is different from general workpiece, the uniqueness of its tooth type and high surface hardness(Like a diamond)Tungsten carbide, the traditional common grinding wheel grinding it's impossible to be.

-Gear grinding-(Intermediate frequency quenching)-Sand blasting-preheating-render-Sprayed tungsten carbide (thickness0.05~0.06㎜)-effection—life2000~5000Wan run meters;

3And the advantage of the tungsten carbide

AAnd more durable than general corrugated roller life and tungsten carbide3~6Times.

B, general corrugated roller tooth depth change is big, the cardboard quality is not stable, the new roller core paper and glue roller clearance should be0.1mm~0.2mm, but when the corrugated roller wear in the middle0.1mm, gap will enlarge, resulting in excessive amount, too much water make cardboard soft and easy warpage;Tungsten carbide tooth depth change small and long paper flat and stable quality.

C, general corrugated roller wear too much among, into a concave, cannot reproduce wide board, waste paper, because both ends can be crushed or not(Degumming blister), then you have to go to the ends of the grinding roller, wide board to go, to maintain the life of the corrugated roller;Tungsten carbide corrugated roll because of wear-resisting, there is no go again after a narrow paper go wide paper and create problems.

DBecause, general corrugated roller wear is fast, so original design depth is higher(Stare blankly rate of large)To ensure life;Tungsten carbide corrugated roll because of wear-resisting, low design depth from the start(Stare blankly rate is small)And long service life.

E, general corrugated roller can't useVBecause stare blankly top if small type and will soon be wear and tear, cardboard will be more and more soft;Tungsten carbide corrugated roll because of wear-resisting don't have this problem.

FAddendum, general corrugated roller wear quickly and, after repair the diameter is much smaller;Tungsten carbide corrugated roll because of wear resistant and wear and less, after the repair is almost the same diameter. And most importantly: tungsten carbide corrugated roll in the whole roll working life, its high stare blankly is almost the same.

Zhengzhou; thermal spraying machinery co., LTD. As the leading enterprise in henan thermal spraying industry,Is a professional engaged in thermal spraying processing and equipment manufacturing research and development of high and new technology enterprise innovation, Supersonic flame spraying equipment, and undertake all kinds of spray processing and mechanical processing business, the thermal spraying technique power is strong, after the hot spraying coating design and coating processing, supersonic flame spraying equipment has experienced, innovative ideas, to solve some key problems in the field of thermal spraying related applications.The company has more multi-purpose spraying room, equipped with a robotic arm, complete all kinds of tooling, can ensure good coating quality.Company also is equipped with lathes, milling machine, drilling machine, and the universal grinding machine can undertake various mechanical processing business, and coating surface grinding business.

The company's aim is: to create the world first-class technology and equipment, to provide customers with high quality and high quality service, honesty, innovation and progress.Actively accept user valuable advice in equipment use and coating processing.Wholeheartedly for the users from all walks of life both at home and abroad to provide quality services!